- today

- label News

- favorite 68 likes

- remove_red_eye 4312 views

Laminates are known for a number of their properties that make the material functional and durable. Are you wondering which product to choose to best meet your expectations? In the article you will find precise descriptions of materials, their properties and applications. Our doypacks consist of the following layers:

PAP – paper

A pulp of organic origin bound on a sieve with a weight of 28 to 200 g/m², produced by placing fibers on a sieve. The paper is produced in the form of sheets or web wound into rolls. After forming the mass on the screen, the paper is dewatered, pressed, dried and smoothed in successive stages of the continuous manufacturing process.

Paper, due to the fact that it is odorless and does not conduct heat, works well in the food industry, for storing or transporting various types of products. Grammage is a key determinant in the selection of paper - depending on the intended mass of material per square meter, we get paper of various thickness - from very thin tissue paper to cardboard - i.e. the thickest paper material. The packaging is marked PAP or kraft paper + number. On the example of our flagship product - flat bottom kraft 1kg - the marking looks like this: Kraft paper60

Kraft paper - paper, made of recycled paper or virgin fibres, available in beige, with a weight of 60 g/m2.

PE – polyethylene

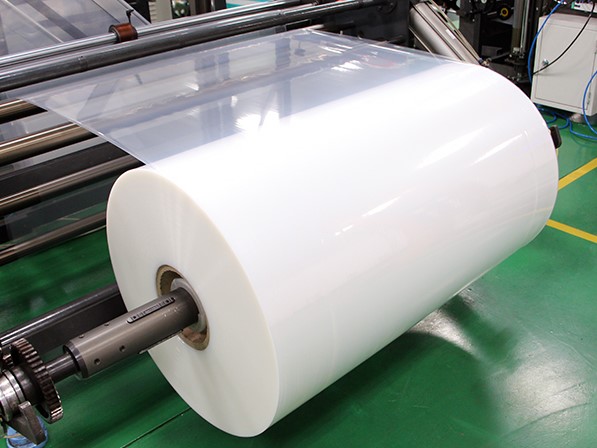

Polyethylene is a material that consists only of carbon and hydrogen. Thanks to this simplicity, polyethylene is used in everyday life as well as in industry. It is most often used for the production of foil - polyethylene is used to make disposable shopping bags, doypacks, caps, containers or tanks. The material has good chemical resistance and excellent electrical insulating properties, is flexible, thermoplastic and easy to process. This range of features makes polyethylene easily used for the production of beverage bottles or cosmetics packaging.

In the packaging industry, polyethylene is very common. In packaging, polyethylene is the innermost layer responsible for contact with the product. In the previously mentioned flat bottom kraft 1kg packaging, PE80, i.e. polyethylene with a thickness of 80 microns, was used. The most important function of polyethylene in the packaging is the heat-sealable properties - thanks to that we can seal the bag using a heat sealer. In addition - it also creates a barrier affecting OTR (oxygen transmission rate).

There are several different types of polyethylene in the systematics (UHMWPE, HDPE, MDPE, LDPE, LLDPE, PEX), but in everyday life the most known are: HDPE and LDPE.

HDPE Polyethylene is used when higher material strength is needed, which is why this polyethylene is called High Density PolyEthylene. It is produced from hard pipes, beverage crates transporters or fuel canisters.

LDPE polyethylene - low density polyethylene (Low Density PE) is used in the packaging industry, in the production of Doypack, Flat Bottom, Stabilo packaging or bags with a side fold.

BOPP – polypropylene

Particularly valued by the industry due to its high resistance to various types of chemical substances. Polypropylene products have excellent insulating properties as well as good air permeability.

BOPP or - Bi Oriented Polypropylene, i.e. double-sided oriented polypropylene, is used in the packaging industry as the outermost layer, serving as a printing medium. The print is made on the inside of this layer, i.e. the one that is then laminated to the middle/carrier layer. Importantly - BOPP is a matt foil, thanks to which you can get a matt finish of the bag without the use of additional refinements - e.g. varnishes.

On the example of one of our flagship Flat Bottom Black 1kg packages - BOPP is the outermost layer with a thickness of 25 microns (BOPP25).

PET film - polyethylene terephthalate

PET is defined as polyethylene terephthalate - a material belonging to the group of thermoplastic polyesters. It is a compound obtained in a polycondensation reaction from terephthalic acid (PTA) or its ester - dimethylterephthalate (DMT) and ethylene glycol (EG).

PET is mainly made of the so-called rigid film ideal for the production of various types of packaging. This means that the material is widely used in many industries, from food to electronic or chemical.

In the case of doypack, flat bottom, stabilo, side fold packaging - PET film gives the packaging stiffness.

vmPet (vaccum metalized Polyethylene terephthalate) - Metalized pet

Polyethylene terephthalate with a metallised layer. VMPET film is a type of composite flexible packaging material, which is created by coating the material with a thin layer of aluminum (so-called metallise). The most commonly used method of vmPET production is the method of vacuum coating of aluminum (hence the name vaccum metalized or VM). Metallic aluminum melts and evaporates, causing aluminum fumes to accumulate on the surface of the plastic film (PET), giving the surface of the plastic film a metallic sheen. Because it not only has the properties of plastic film, but also the properties of metal, it is a kind of packaging material with low cost, beautiful appearance, excellent performance, and most of all, high barrier. High barrier properties affect the OTR (oxygen transmission rate), and the stiffness of the PET film improves the resistance of the material - which makes doypack packaging resistant to tearing.

Translating into normal language ;) - this layer is responsible for the strength / stiffness of the bag and for keeping the product fresh. Its additional feature is that it is silver. This can be used in the creation of refinements - e.g. gilding or selective silvering.

AL – Aluminum

Aluminum is a material highly valued for its plasticity - and thus, the possibility of processing in many ways. Aluminum is a material that accompanies us every day, in every sector of the economy - it is used in the production of cans, caps, aerosol packaging or in the kitchen, in the form of aluminum foil or cake tins.

A layer of aluminum foil is also used in the packaging industry. In our packaging - flat bottom kraft 1kg, we use a 7-microns thick layer of aluminum foil. Aluminum is characterized by the highest barrier properties, i.e. it is the least oxygen permeable.

Therefore, packaging with this layer will maintain the high value of the product for the longest time of all. At the same time, especially in Western countries, the aluminum layer is unwelcome to end consumers because it is considered not ecological. The above-mentioned KPET is a compromise.

Aluminum, like vmpet, is silver - this feature allows the use of selective silvering and gilding. We will write another article about how such gilding is made - an article about prints ????

KPET

KPET is a PET film coated with PVCD - poly(vinylidene chloride).

This film is a novelty on the packaging market. The barrier properties are matched by vmpet being at the forefront of barrier films. This film is transparent, so it can be used for packaging with a window. If it is important to show the product and, at the same time, preserve its taste / food qualities for a long time - KPET is a perfect solution.

In our offer, the KPET layer is present in flat bottom black kraft packaging, thanks to which the packaging is characterized by high barrier properties and ecological appearance (no aluminum / metallized layer).

EVOH (Ethylene Vinyl alcohol) - ethyl vinyl alcohol

Ethylene vinyl alcohol (EVOH) is a formal copolymer of ethylene and vinyl alcohol. Since the latter monomer is mainly in the form of acetaldehyde tautomer, the copolymer is prepared by polymerizing ethylene and vinyl acetate to form a poly(ethylene vinyl acetate) (EVA) copolymer followed by hydrolysis. The EVOH copolymer is defined by the molar content of ethylene: grades with lower ethylene content have better barrier properties; grades with higher ethylene content have lower extrusion temperatures.

Ethylene vinyl alcohol copolymer resins are produced from EVOH in the polymerization process. EVOH ethylene vinyl alcohol copolymer resins are used in the packaging industry (for food, heavy industry, cosmetics, etc.) to improve oxygen barrier (OTR). Thanks to their use, a given product/article retains its properties longer and is protected, e.g. from odours, the influence of weather conditions and the action of fats. The level of oxygen barrier depends on the level of EVOH vinyl alcohol content.

Despite its high oxygen barrier, EVOH is a poor water vapor barrier. Therefore, in multi-layer packaging, it is usually used as an inner layer isolated from the outside by a protective layer, e.g. of polyethylene. EVOH copolymer is also not resistant to the harmful effects of acids.

PE/PE-EVOH laminate has an additional important property. How is it possible, since it consists of PE and EVOH - i.e. 2 layers? Well, RecyClass (a non-profit initiative that develops recyclability assessment protocols and scientific methods for testing innovative plastic packaging materials that serve as the basis for designing recycling guidelines for the European Union) has classified this material as fully recyclable.

RecyClass, after numerous tests, has proven that if EVOH in the laminate is present in an amount of less than 6% of the component weight, it has no effect on the recyclability, so it is classified as "A", and above 6% it has only a small impact on the recycling streams and reaches class "B".

Therefore, soon you will be able to buy PE / PE-EVOH packaging from us, which will have great barrier properties for the product, but at the same time will be fully recyclable.

In addition to the packaging industry, EVOH is also used in construction (pipes) and in medicine (radiology).

CPP - Cast Unoriented Polypropylene (cast polypropylene, unoriented)

CPP is a subtype of polypropylene (PP) film. Polypropylene films are low-density plastic films known for providing excellent package integrity while providing an excellent moisture barrier, making them stable and, when used in packaging, extending product shelf life.

One of the most important features of the CPP film is its high transparency. This is why in our packaging warehouse CPP foil is in packages with a window - to show the product that is inside the package.

PLA - polylactide (polylactic acid)

Polylactic acid comes from renewable resources and is completely biodegradable itself. Thanks to this, it is used, among others, in the medical sector, for the production of screws, rods or plates, which are expected to biodegrade within a year. PLA is also used in the food industry for the production of packaging (including tobacco packaging).

PLA is an environmentally friendly, biodegradable and compostable film. Production is carried out using the extrusion technique, from biopolymers produced from biodegradable raw materials based on corn grains. The film was developed as an alternative to the petrochemical materials described above. This film has FDA approvals for contact with food, as well as biodegradability and compostability (according to EN 13432).

What is important - PLA shrinks when heated. This makes it suitable for a range of packaging applications where it can replace plastics such as polyethylene. Simply put, PLA can replace the PE layer - the main feature of which, as we all know, is the heat-sealable properties (it allows you to heat the bags). PLA also allows you to secure the bag by heat-sealing.

PLA is available in our offer in compostable packaging.

It is worth adding here that the packaging we offer is certified by TUV Austria Home Compostable. This means that the packaging decomposes in home composters, as long as composting conditions prevail in them.

Laminates – a combination of materials in order to obtain the most efficient set of features

How to distinguish laminates and know what products they are made of? Below you will find a clear list explaining the abbreviations, so that you can quickly and easily choose the material for your needs.

PAP/PETmet/PE

In the case of manufactured laminates, the layers are fed from the outside, i.e.:

- PAP - paper (the outermost element of the laminate). First of all, paper performs informative, decorative or promotional functions - thanks to the possibility of printing on it.

- VMPET/PE – metallised PET/polyethylene. It is a laminate of two films - VMPET and PE. VMPET is responsible for the barrier properties of the packaging, while PE is the layer responsible for contact with the product and sealability of the bag.

BOPP/VMPET/PE

It is a laminate consisting of BOPP as the outermost layer on which the print is made. The imprint on BOPP comes out matte. VMPET is the barrier layer and PE is the inner layer.

PE/PE + EVOH

Thanks to its low EVOH content, this laminate is considered a fully recyclable mono-material.

- PE - polyethylene. It is primarily an inert material in relation to food products. It does not enter into any chemical reactions, is odorless and has no taste. In coffee packaging, it has an insulating function and is responsible for the heat-sealable properties of the bag.

- PE + EVOH – polyethylene + ethylene vinyl alcohol copolymer resin. This is a great combination because EVOH protects the inside of the packaging from outside gases and has excellent barrier properties.

Kraft paper60/Al7/PET12/PE80

Kraft paper with a weight of 60 g - (Kraft paper is a material that is made of virgin fibers or recycled paper). Coffee doypacks are lightweight, odorless and have excellent mechanical properties. Paper performs informative, decorative or promotional functions - thanks to the possibility of printing on it.

- Al7 - aluminum with a thickness of 7 microns. Aluminum performs both protective and decorative functions.

- PET12 - PET with a thickness of 12 microns

- PE80 - Polyethylene with a thickness of 80 microns.

The markings on the paper are in terms of paper grammage - in microns.

BrownKraftPaper50/MilkyPLA40

50g kraft paper

- MilkyPLA40 – polylactic acid with a thickness of 40 microns. In packaging, a valuable advantage of polylactic acid is the quickly decomposing material in compost conditions. The high stiffness and strength of the material ensure that the packaging does not deform.

40KRAFT+12PET+60CPP

- 40g kraft paper

- PET - 12 micron polyethylene terephthalate. A hard, strong surface that is also sufficiently flexible. PET provides good sliding properties and is a great electrical insulator. Chemical resistance to acids and other chemicals is an added advantage in protecting packaging/products made of polyethylene terephthalate.

- CPP - 60 microns thick. Responsible for the safety of packaging / product, due to its resistance to abrasions and bruises. Along with that, it is the layer that best protects the contents of the package. In combination with PET, it creates an extremely strong protective layer.

Doypack packaging is the most appropriate solution for coffee packaging, company packaging, paper tobacco packaging or any food bags.

Bedruckte Verpackung

Bedruckte Verpackung Grüner Kaffee

Grüner Kaffee Recycelbare Verpackung

Recycelbare Verpackung Kompostierbare Verpackung

Kompostierbare Verpackung Standbeutel mit Blockboden

Standbeutel mit Blockboden Verpackung K-Seal

Verpackung K-Seal ze struną

ze struną Standbodenbeutel

Standbodenbeutel Stabilo Bags

Stabilo Bags Faltenbeutel

Faltenbeutel Verpackung für...

Verpackung für... Nach Gewicht / Kapazität

Nach Gewicht / Kapazität Andere produkte

Andere produkte Die Proben

Die Proben Alle produkte

Alle produkte Zubehör/Gadgets

Zubehör/Gadgets